The Aer-O-Scope Colonoscope is designed to fundamentally change the way colorectal cancer screening will be performed. It is designed to help GI practices and hospital outpatient departments meet escalating demand for colorectal screening with a reliable, easy-to-use and cost-effective disposable colonoscope. Pre-clinical and clinical trials were conducted in Israel and the US to substantiate the Aer-O-Scope system’s 360° visualization capabilities as well as safety and intubation rate targets.

Giview workstation

Disposable Colonoscope System

Role

R&D ME, Team lead

Company

GI View

Year

2013-2017

System Architecture

The Aer-O-Scope Colonoscope System consists of two primary components - a workstation and a disposable scanner (Colonoscope Component)

The Aer-O-Scope workstation provides all of the necessary elements to operate the disposable scanner. These include CO2, water, suction and air pressure, as well as the power supply for the camera and illumination. The Aer-O-Scope workstation also receives and processes transmitted data from the camera and scanner, including pneumatic controls and pressure measurements used by the control software to manage advancement within the colon. The work station is equipped with a physician device interface. The ergonomic joystick is at the core of the work station, enabling intuitive control of navigation, insufflation, irrigation, and suction.

Below are few of the mechanisms and sub assemblies we built to meet the usability and feasibility needs.

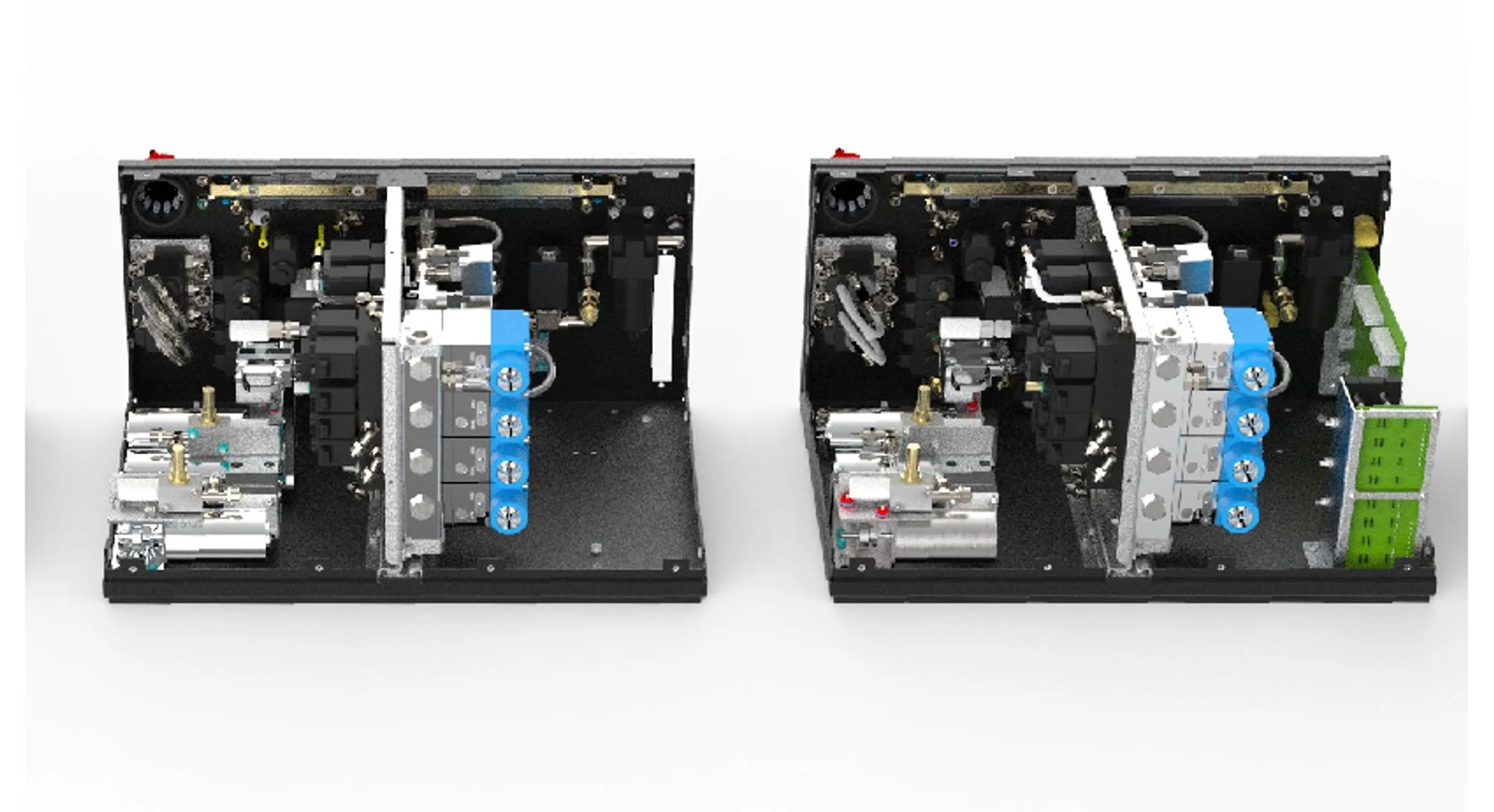

Pneumatic Unit

The pneumatic unit is the “heart” of the workstation. It contains all the pneumatic components and electronics responsible for proper operation of the system: air compressor, air pumps, pressure regulators, flow meter, pressure sensors, valves, and pressure relief valves. Problematically, in the previous design, the pneumatic components were mounted in a way that did not allow maintenance without a on-site technician. Because the pneumatic unit assembly contains many critical components that if they failed would cause system failure, it was important to design an unit that could be easily replaced in case of failure.

All the pneumatic critical components were packed into an anodized aluminum sheet metal box that could be easily connected and disconnected to the workstation. Thus, in the event of a failure, a user would need to open the side service door, remove the pneumatic unit, and slide in a new one. A new unit could be obtained by order from the company.

Sub-assemblies were assembled and tested separately, and then combined into the pneumatic unit once they had been completed. This process shorted assembly from weeks to a few days and was overall easier and simpler.

Water Bottle Mechanism

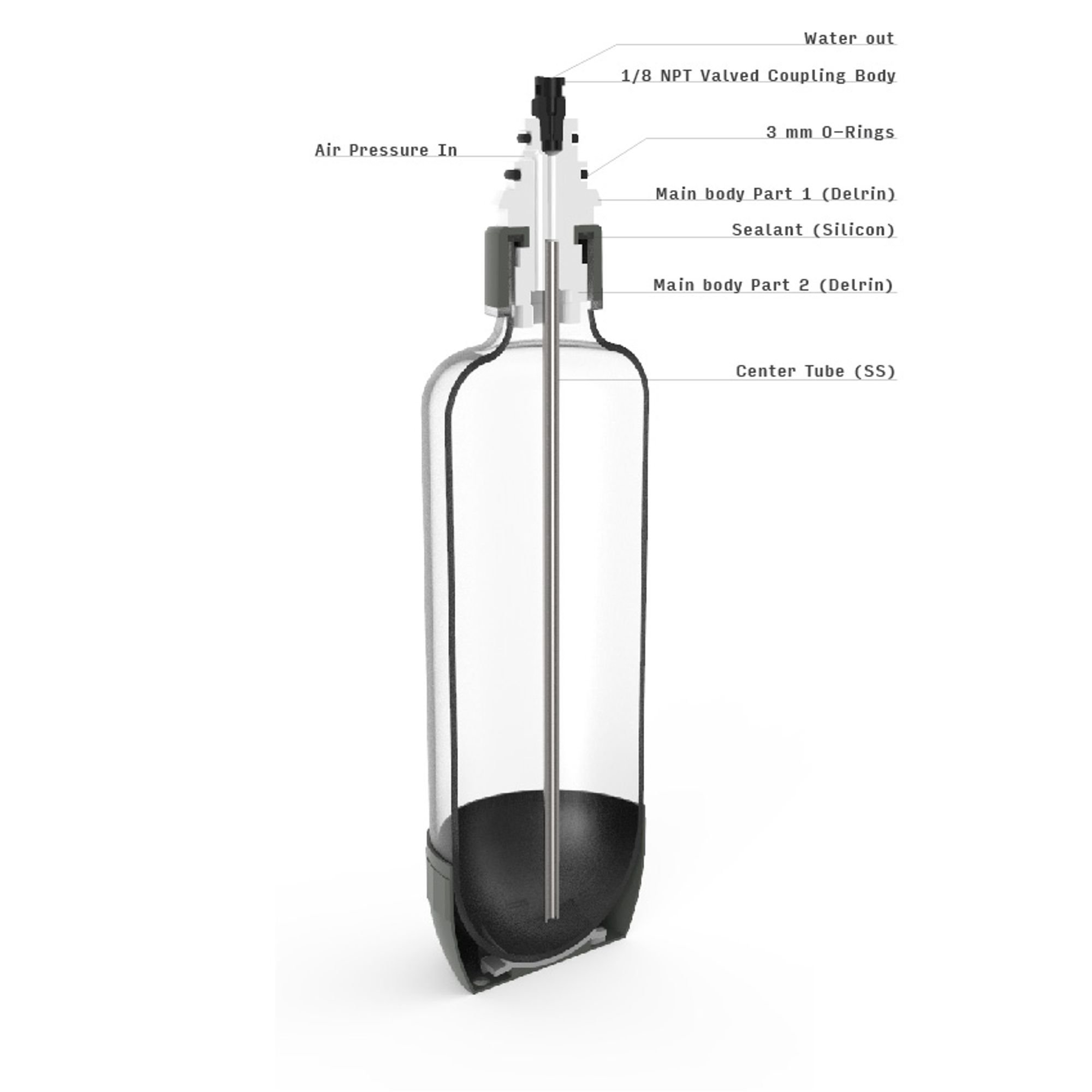

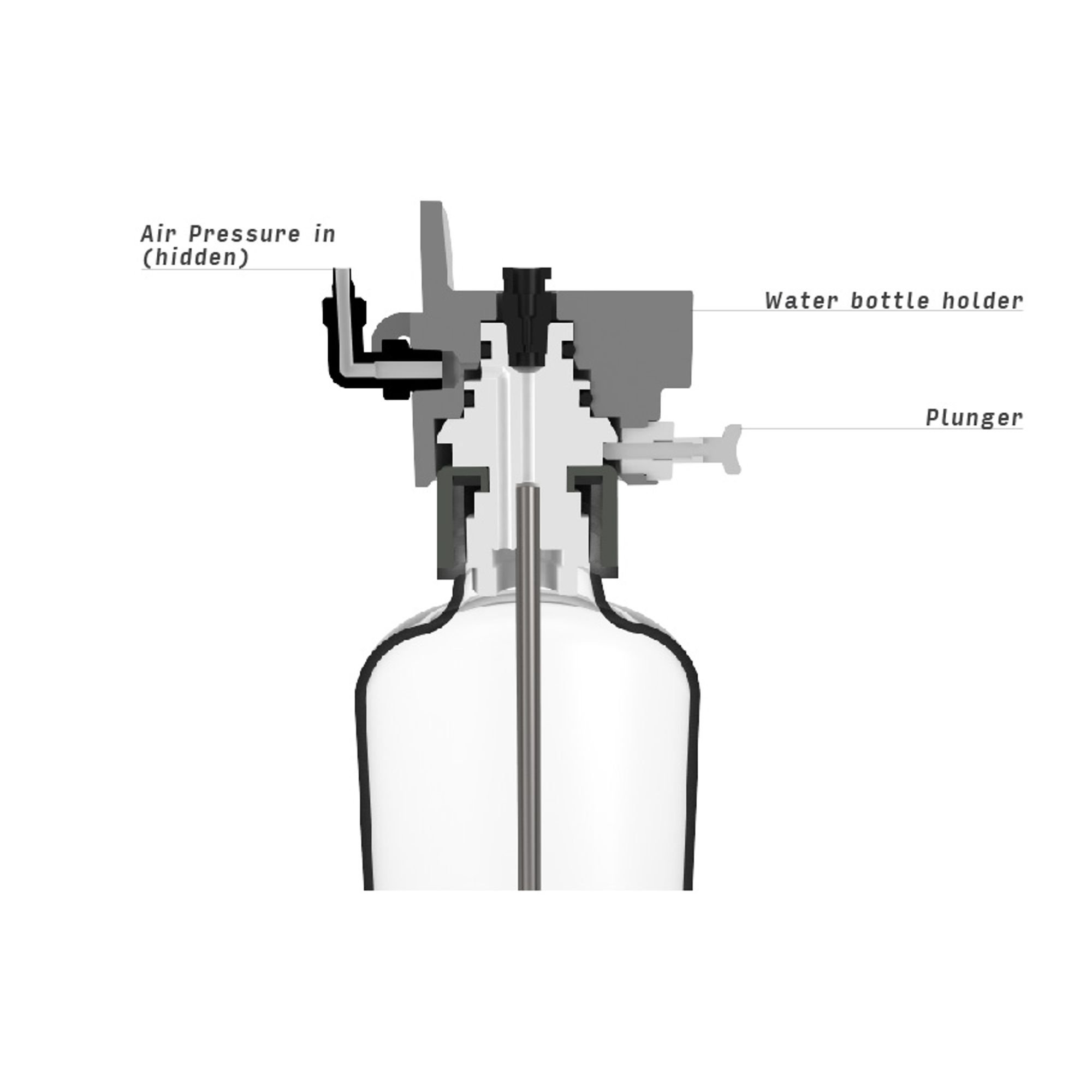

The workstation includes a high pressure compressed water bottle to provide water for cleaning the camera lens. The bottle is filled with water at the beginning of every procedure. To drive the water out of the bottle, a high air pressure (2 bar) fills the top of the bottle which in turn pushes the water through the center tube to the scanner lens.

Even though the procedure happened frequently about 10 times a day - the previous design’s user experience was not optimal. It required connecting the water output tubing first and then connecting the air pressure tubing. Failure to complete these step in order resulted in water spraying the water straight up. Furthermore, the visual appearance of two tubes had to be improved.

The ideation started with exploration of off the shelf single/dual pneumatic connectors and ways to mount them to the water bottle cap. The goal was to achieve both the water and air pressure connection in one easy action that eliminated the risk of a faulty connection.

The final design eliminated the need for an air pressure connector. Upon insertion of the water bottle into the holder, the bottle is locked into place using a spring-loaded plunger and the air pressure automatically connects.

Filter Units

A major risk in colonoscopy procedures is cross-contamination, which occurs when pathogens pass from one patient to another through liquid. The previous design of the Aer-o-scope prevented cross-contamination by including a filter in each disposable colonoscope. This solution made producing the disposable colonoscope portion expensive. I designed a more cost-effective solution by including the filter in the Workstation rather than the disposable colonoscope.

The filter detected liquid back-flow, contained it, and alerted the operator. The operator could then dispose of and replace the contaminated filter at the end of the procedure. Because back-flow does not occur frequently, this increased reusability of the Aer-o-scope machine, causing the overall cost of operating the machine to decrease while maintaining adequate safety.

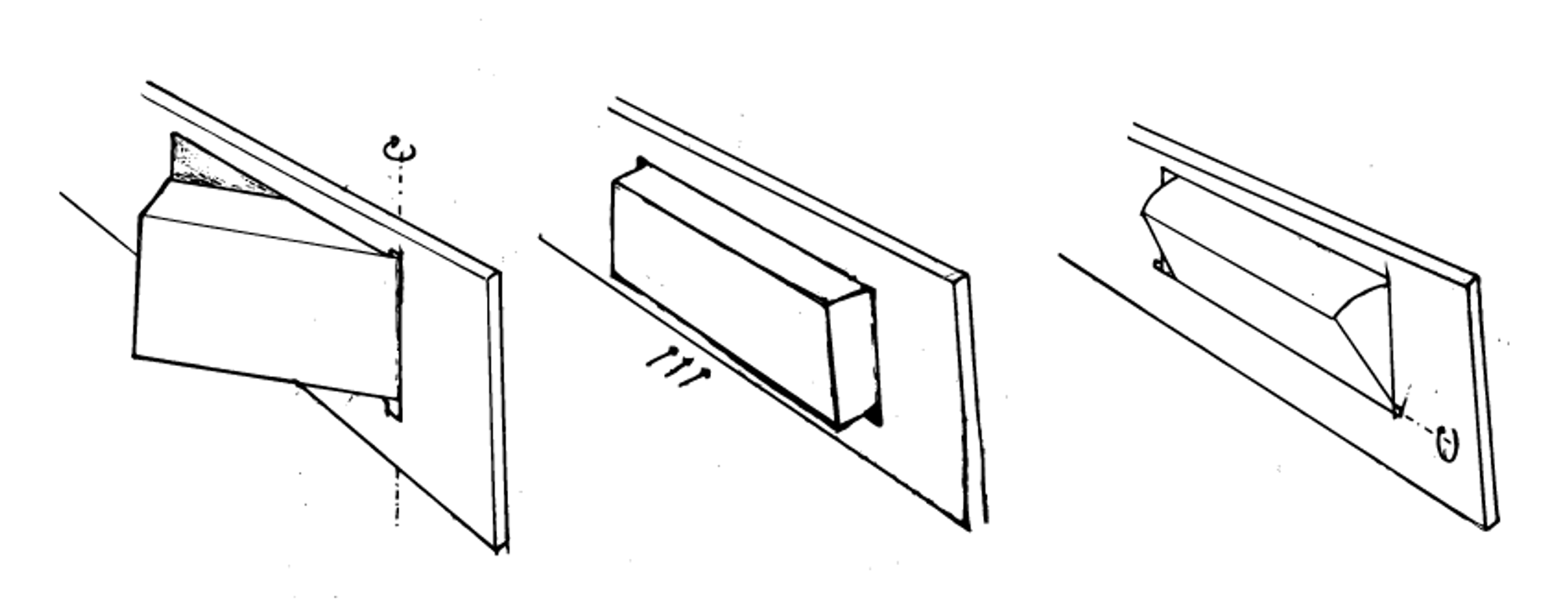

The ideation process started with consideration of the form of the filter and a user experience’s when replacing the `filter unit with a new one.

Vertical rotation | linear sliding | horizontal rotation

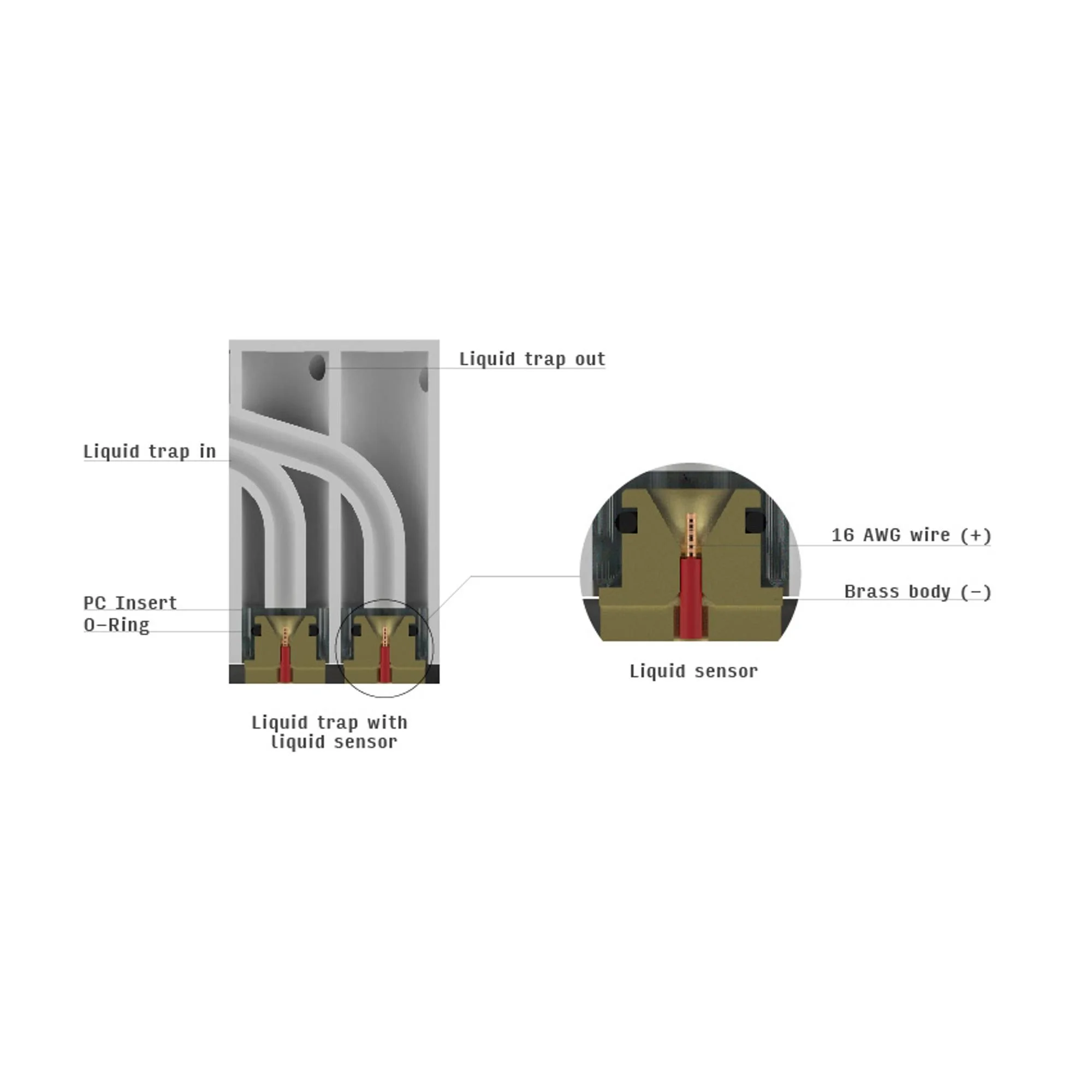

The next step was to evaluate OTS method for fluid sensing. None of the availble methods adequately addressed the problem, however. So we decided to test a custom design.

The sensor contained both a capacitor to detect liquid and a funnel to catch liquid. When no liquid was encountered, the sensor maintained a voltage through two non contact concentric conductive objects (brass body and 16 AWG copper wire). The introduction of liquid would change the voltage. The sensor was placed at the bottom of the fluid trap, a location that every drop of liquid would necessary need to pass through if it were to flow back to the workstation.

The filter unit integrated all four different functions - water trap, liquid sensor, biological filter, and pneumatic front interface - in one 3D printed enclosure. By combining all of these functions into one housing, The possibility of leaking is reduced significantly - A necessary condition for proper operation of the product.

Workstation Packaging

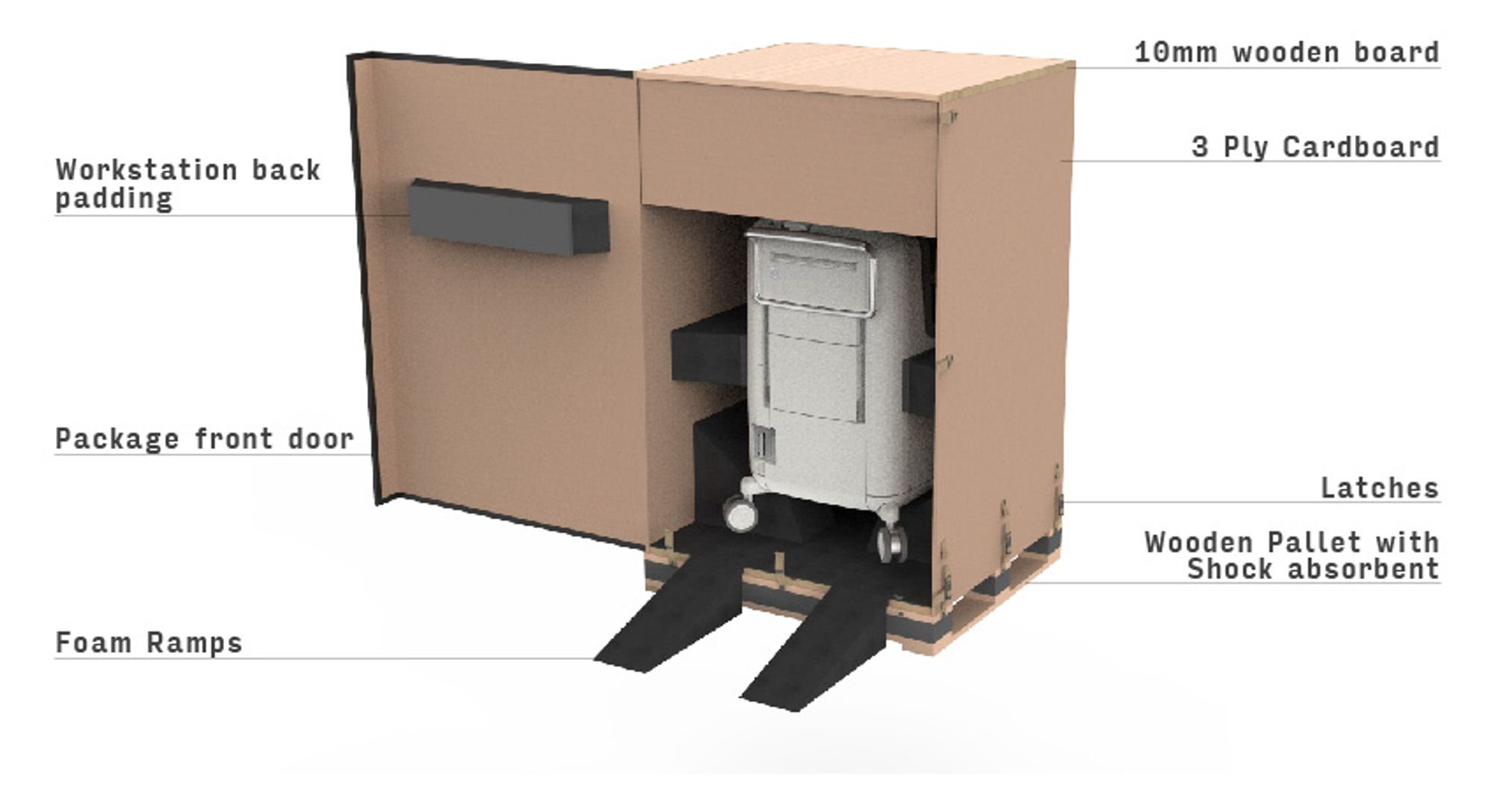

The goal of this sprint was to research, design, manufacture and test a single-use package that would meet CE and FDA requirements and also allow for safe delivery of the workstation and its accessories overseas to the United States for clinical trials. This was particularly exciting because it was the culmination of a quick design process and the first time the company shipped the machine overseas.

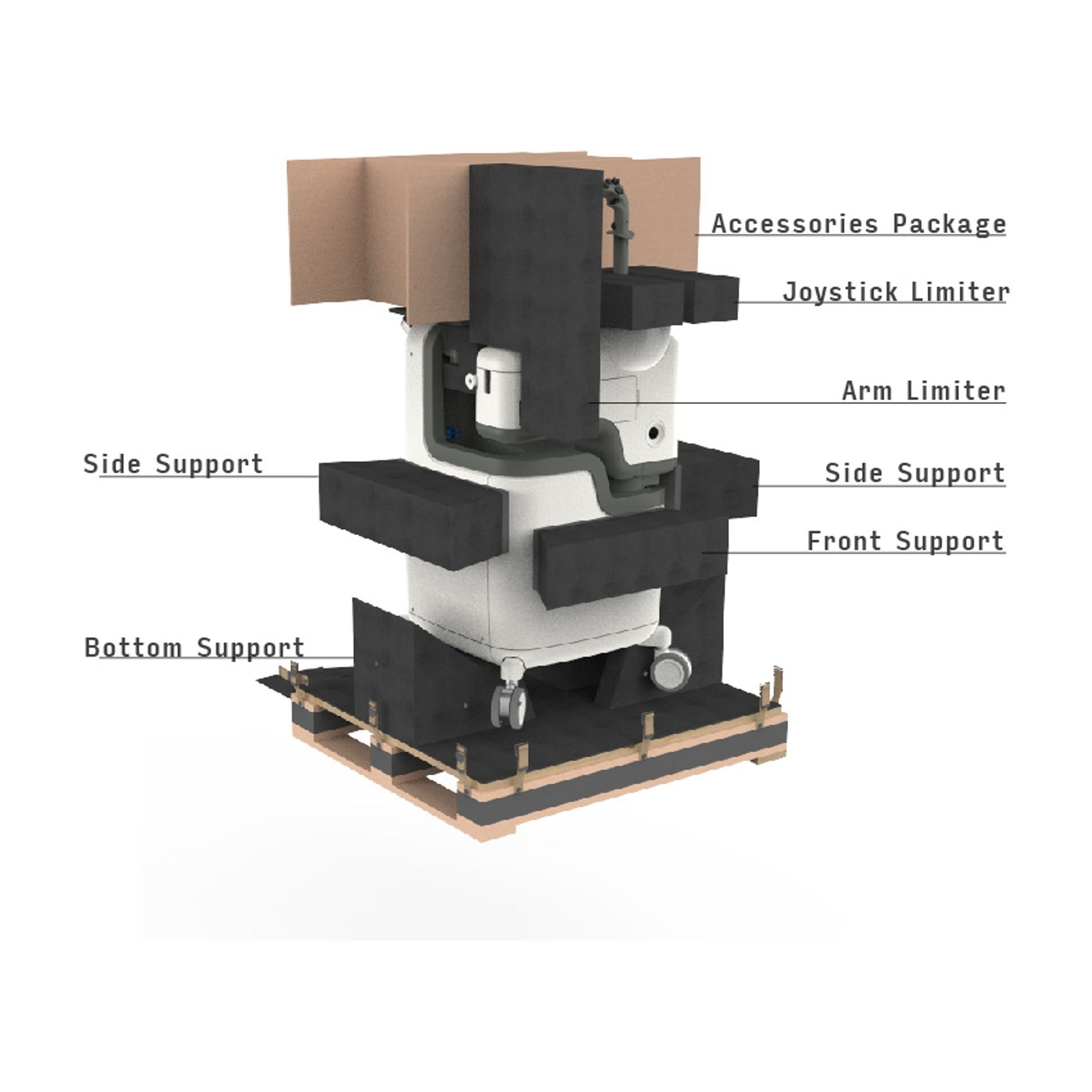

The package design includes a wooden pallet for a fork lift, with three ply cardboard walls and polyethylene foam paddings. To ease packaging and unpackaging the workstation, latches secured the outer walls and top of the package to the bottom wooden pallet. Releasing the latches allowed the outer walls and top of the package to be easily removed.

The design considered the relevant standards for shipping (ASTM D4169 and ASTM4332), including drop tests, vibration profile, and environmental hazards. It was verified through simulated field conditions and through successful shipping of 2 units that were used for clinical trials